[PROPERTIES] How to make a taper from composite T section to composite I?

The number of points to define the section in I-end and J-end of the

taper section to be generated has to be same.

Since a Composite T (say end I of taper section) will have lesser defining points ( O ) as compared to Composite I section (end J ) ,

the tapered element could not be generated. However an as an alternative, we could define T section with so many points as that of I section and generate the tapering.

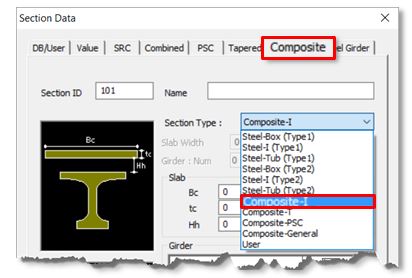

Under Properties > Section Properties, click Add > Composite tab > Composite I option from the drop down menu,

enter the data as per the guide diagram shown below and generate the required I section.

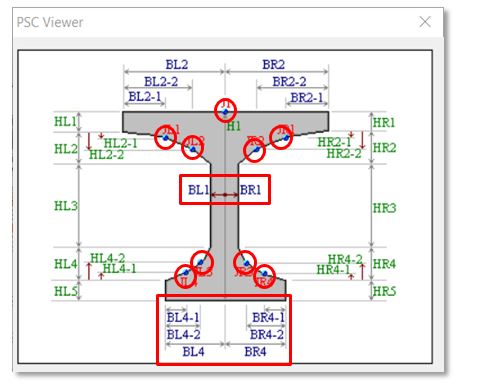

To generate a composite T section, using the composite I girder option, enter the BL1 and BR1 values slightly lesser (say, 0.5mm lesser) than the BL4 and BR4 values. By doing so, the additional points required would have been entered, still retaining the sectional properties of a T section. By this way the tapering of section could be

accomplished. Once the two sections are generated, the tapered section can now be made

using these two section properties.

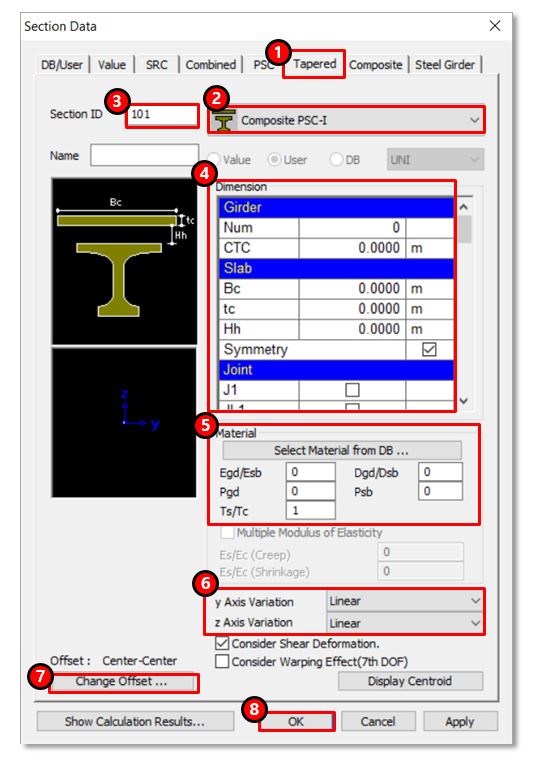

To generate such tapered section, follow the steps below in sequence:

Click on Properties > Section Properties > Add

1. Click on Tapered

2. Select Composite PSC-I

3. Enter Name

4. Enter basic data like slab width, thickness, etc and import the “Size-I” and “Size-J” sections. These would be the sections that are generated using Composite I girder option.

5. Enter material data for equivalent section property calculations

6. Select they type of variation (Linear, Parabolic or Cubic)

7. Modify the offset as required

8. Click OK

taper section to be generated has to be same.

Since a Composite T (say end I of taper section) will have lesser defining points ( O ) as compared to Composite I section (end J ) ,

the tapered element could not be generated. However an as an alternative, we could define T section with so many points as that of I section and generate the tapering.

Under Properties > Section Properties, click Add > Composite tab > Composite I option from the drop down menu,

enter the data as per the guide diagram shown below and generate the required I section.

To generate a composite T section, using the composite I girder option, enter the BL1 and BR1 values slightly lesser (say, 0.5mm lesser) than the BL4 and BR4 values. By doing so, the additional points required would have been entered, still retaining the sectional properties of a T section. By this way the tapering of section could be

accomplished. Once the two sections are generated, the tapered section can now be made

using these two section properties.

To generate such tapered section, follow the steps below in sequence:

Click on Properties > Section Properties > Add

1. Click on Tapered

2. Select Composite PSC-I

3. Enter Name

4. Enter basic data like slab width, thickness, etc and import the “Size-I” and “Size-J” sections. These would be the sections that are generated using Composite I girder option.

5. Enter material data for equivalent section property calculations

6. Select they type of variation (Linear, Parabolic or Cubic)

7. Modify the offset as required

8. Click OK

| Files | ||

|---|---|---|

|

||

|

||

|

||

|

|